Trane / Mitsubishi City Multi VRF Service

San Diego's VRF Expert: Mitsubishi Certified Technician with 30 Years of HVAC Experience Ready to Meet Your VRF Requirements. Offering Troubleshooting, Equipment Installation Corrections, Unit Upgrades, Compressor Replacements, and Comprehensive Repair and Service. Customized Maintenance Programs Designed for Every Application. Consulting Services Offered for Upgrades or New Projects.

Trane / Mitsubishi City Multi Maintenance

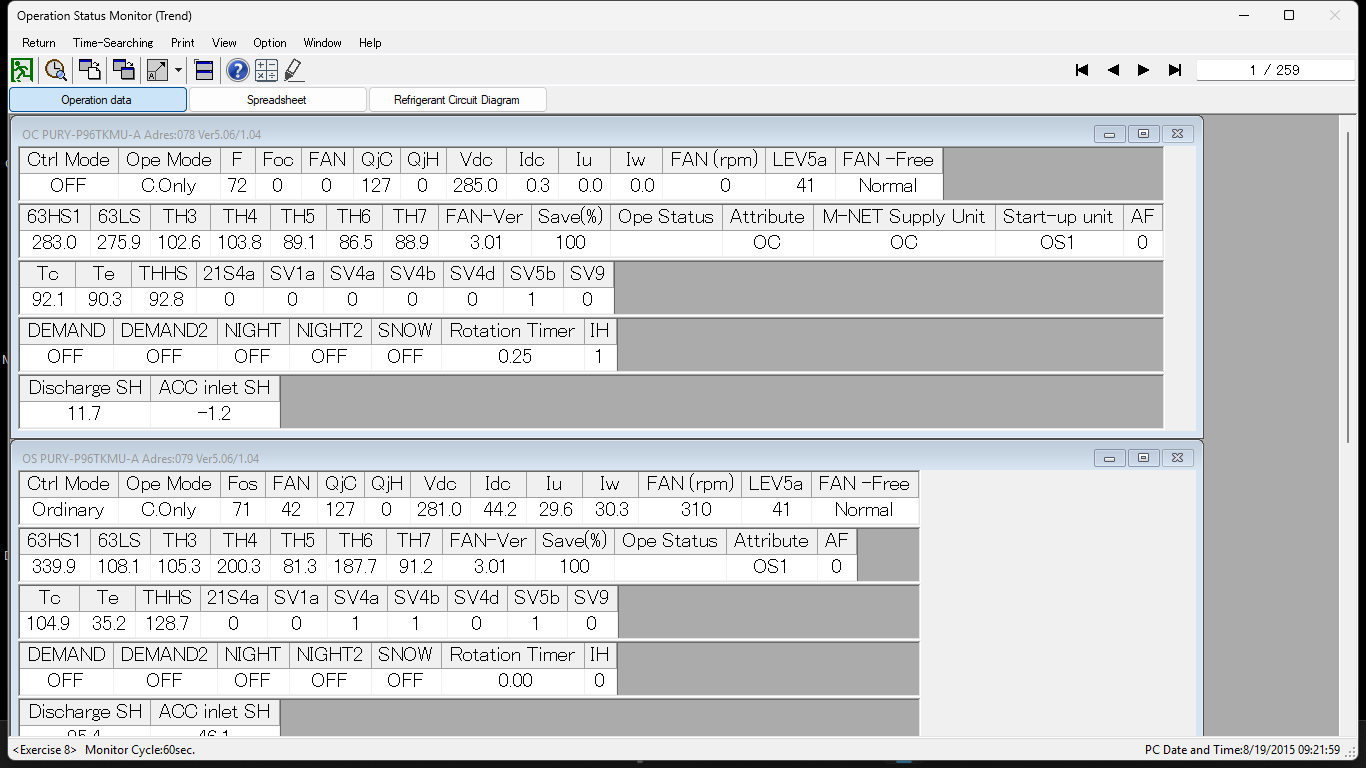

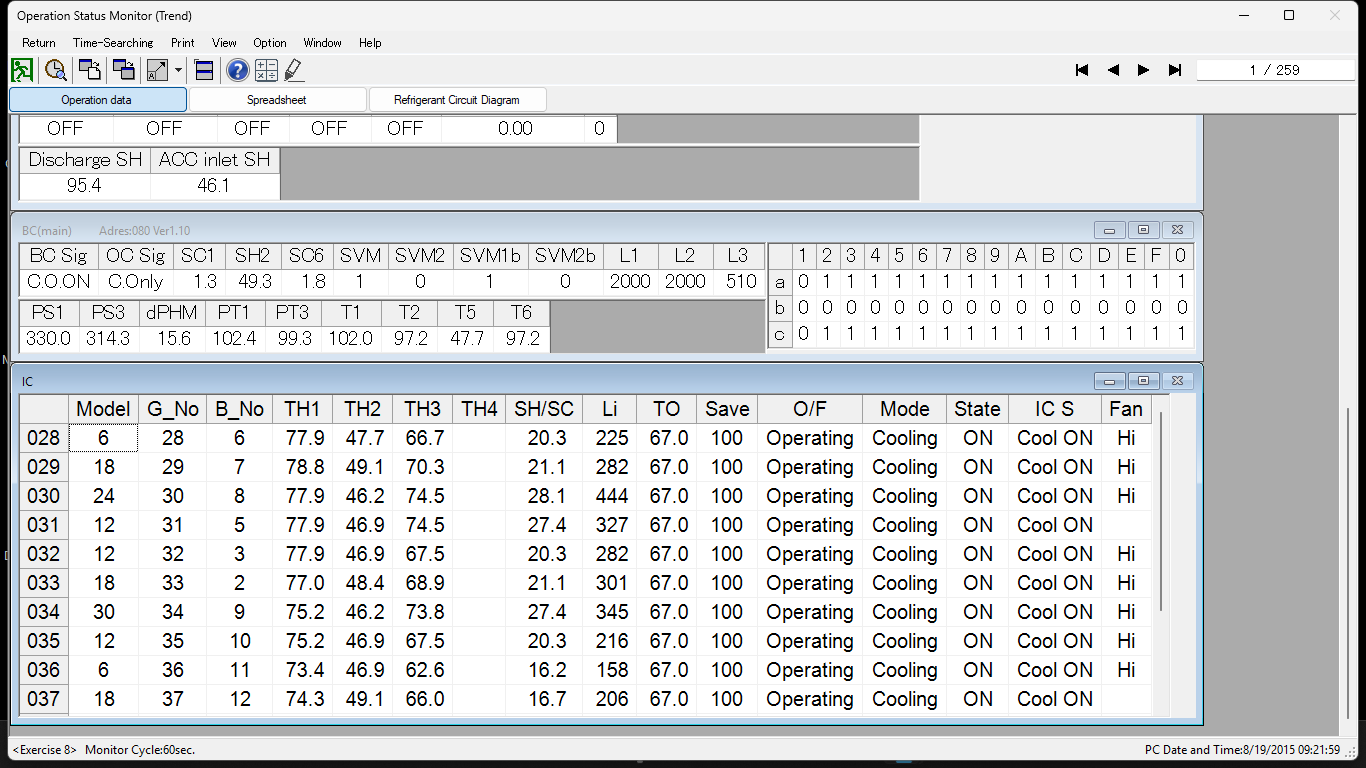

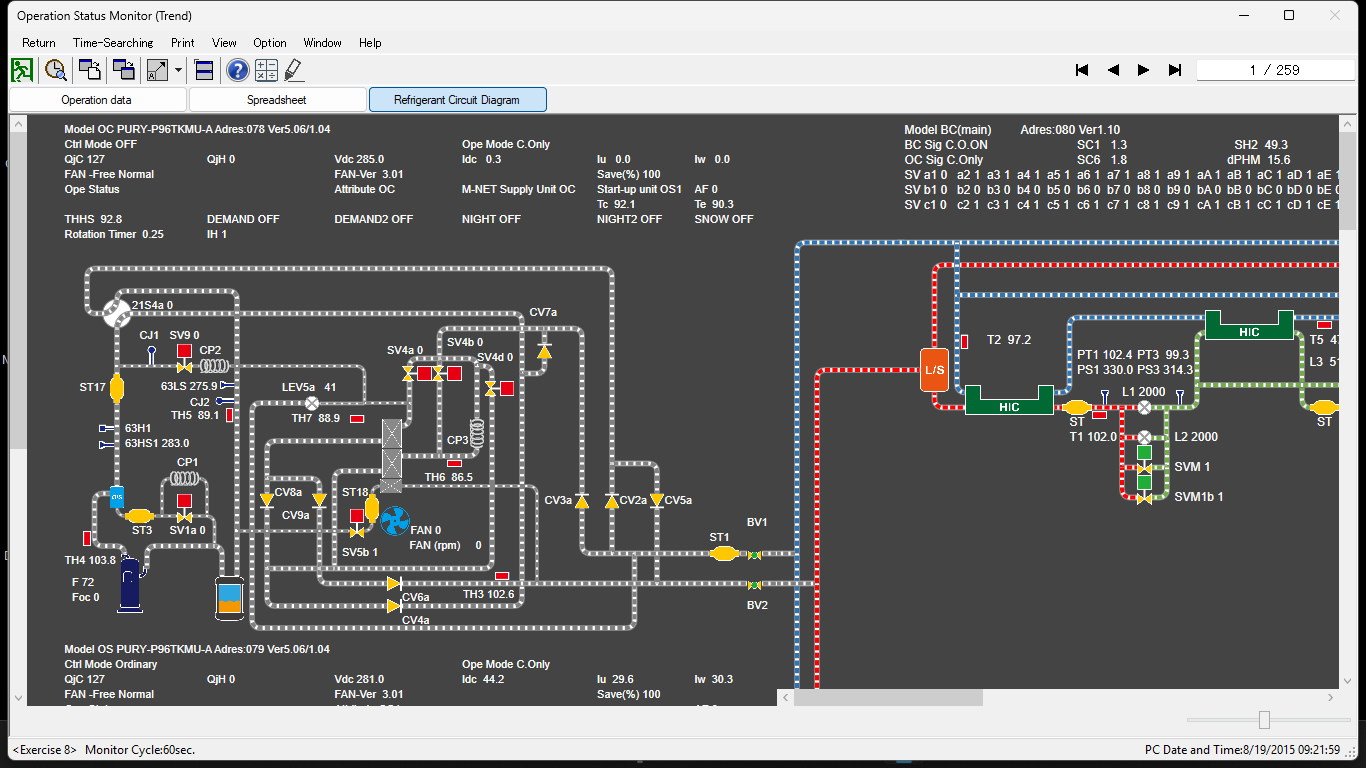

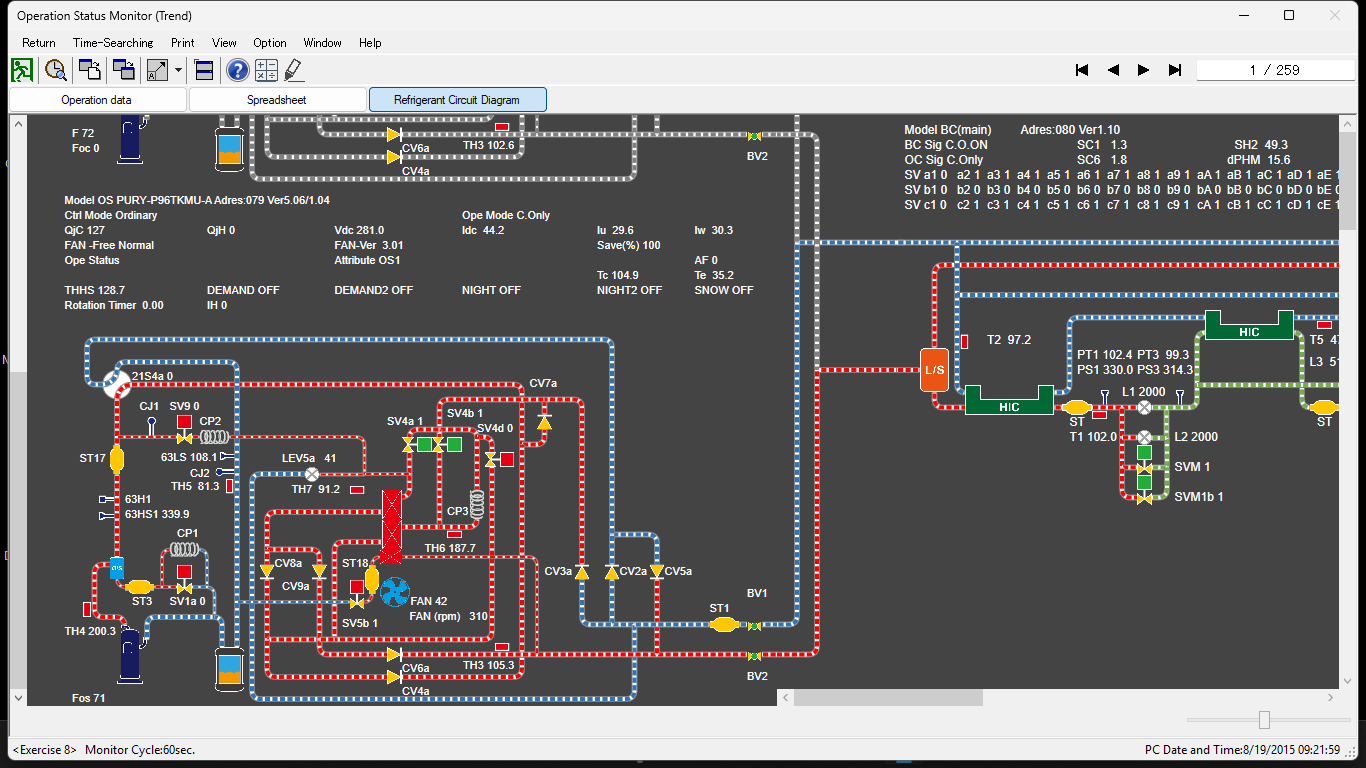

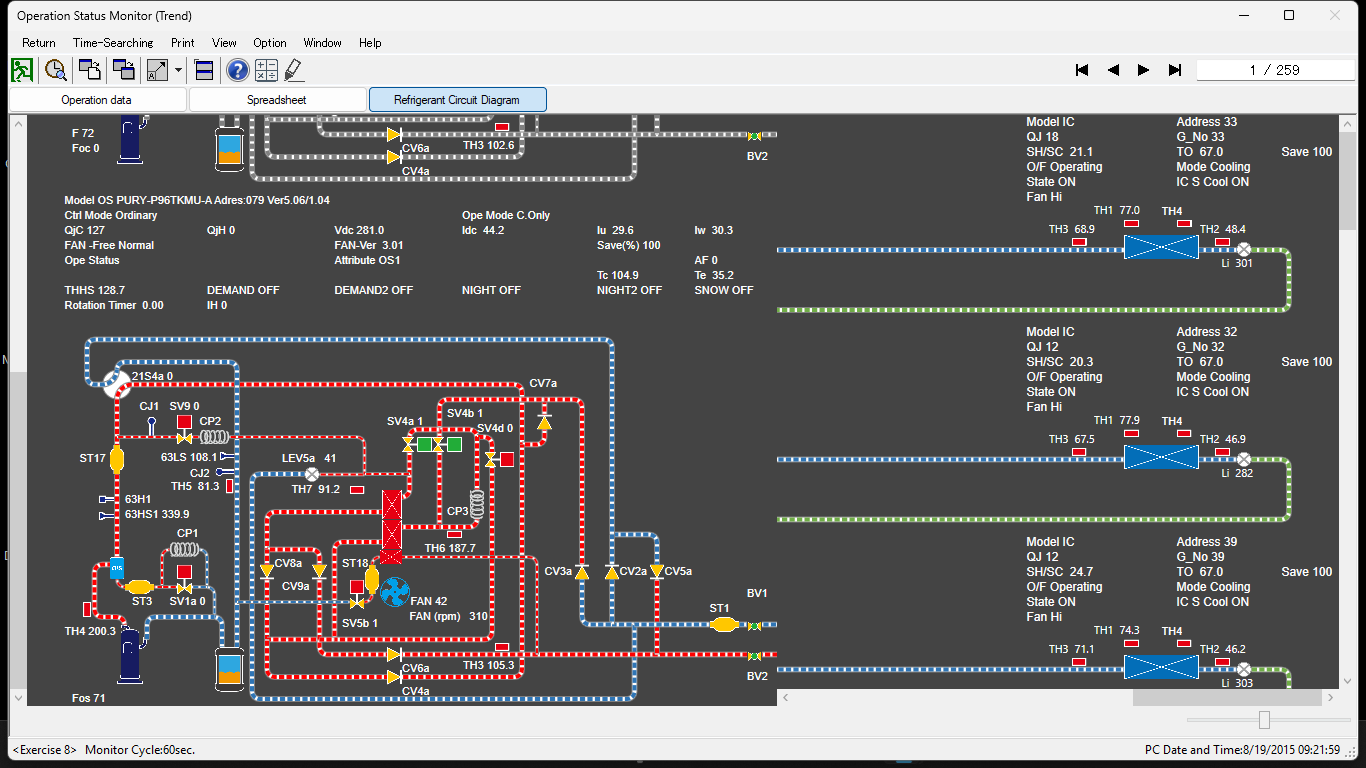

Regular high-level maintenance is essential for the proper functioning of VRF system equipment. Each outdoor unit is equipped with temperature sensors, EEV valves, solenoid valves, and four-way valves. Furthermore, it supports various electronic PC boards, including a main board, power supply, inverter board, fan boards, and noise filters. Notably, some outdoor units can incorporate as many as 11 PCBs. In contrast, indoor units generally comprise four or five sensors, an EEV valve, along with branch box valves and additional sensors. When evaluating the entire system, the total number of components can reach into the hundreds. Each of these components requires routine inspection, testing, and recalibration. Following established maintenance procedures is vital to ensure optimal performance and extend the system's lifespan.

Mitsubishi City Multi Maintenance Tool

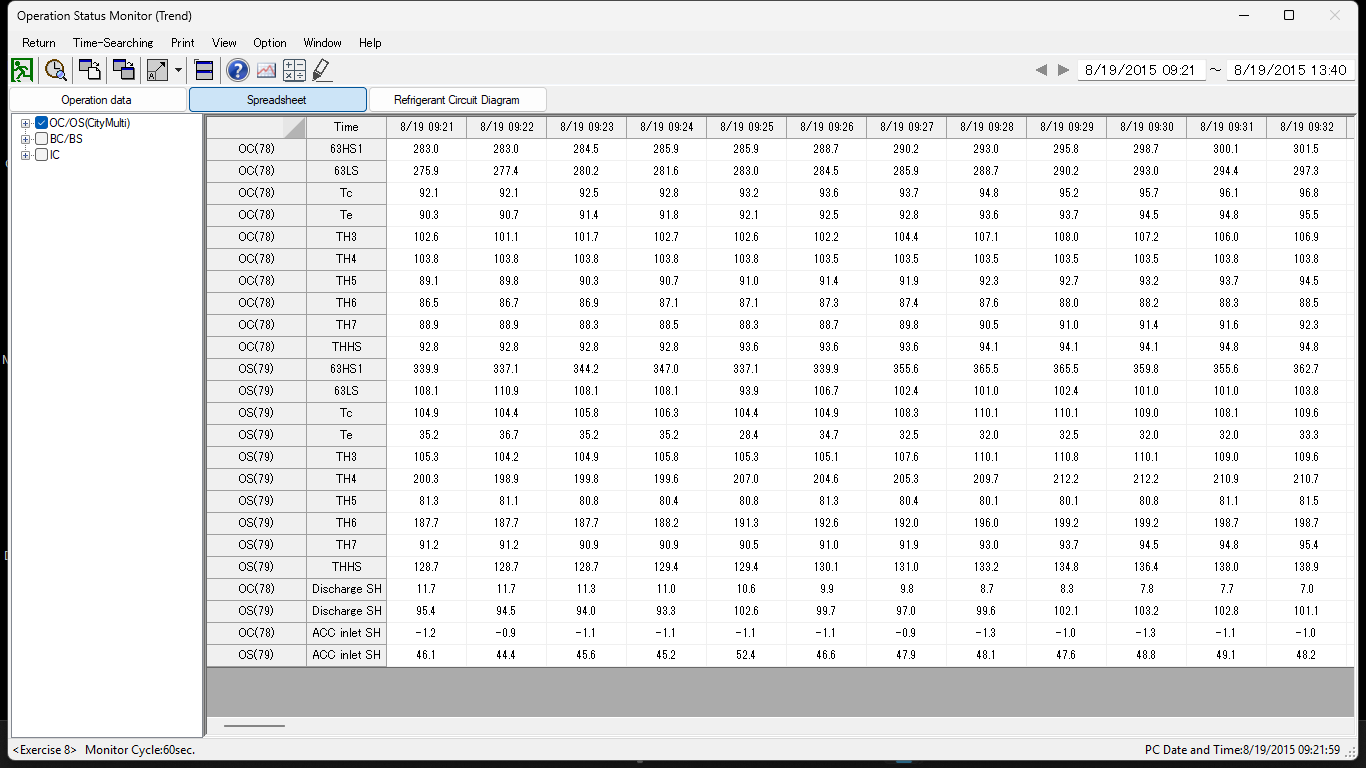

The volume of data generated by a VRF system can be quite daunting. There may be hundreds or even thousands of data points to assess when evaluating system performance. What indicators signify a low charge or liquid flood back? These are the two most significant threats to compressor health. Regular monitoring and analysis are essential for identifying potential issues before they lead to serious damage. In addition to the physical upkeep of the equipment, thorough data analysis with our Maintenance Tool is crucial for maintaining a healthy system. Reach out to us today; your system might qualify for a complimentary check-up.

Mitsubishi System Remote Monitoring

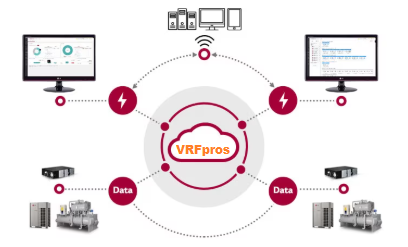

Access equipment data and diagnostic tools remotely to troubleshoot issues, thereby minimizing the necessity for on-site technician visits and reducing associated labor and travel costs. Real-time monitoring of HVAC equipment's health and performance enables technicians to identify potential issues early, preventing costly downtime. Technicians receive instant error alerts for malfunctioning HVAC systems. Maintenance visits can be scheduled according to the actual status of the equipment. This approach ensures that your technicians arrive with the appropriate tools, parts, and expertise, enhancing the effectiveness of maintenance visits.