LG Multi V VRF Service

San Diego VRF Expert: LG Certified Technician with 30 Years of HVAC Experience to Address Your VRF Requirements. Specialized in Troubleshooting, Equipment Installation Corrections, Unit Upgrades, Compressor Replacement, and Comprehensive Repair and Service. Customized Maintenance Programs Offered for Every Application. Consulting Services Available for Upgrades or New Projects.

LG Multi V Maintenance

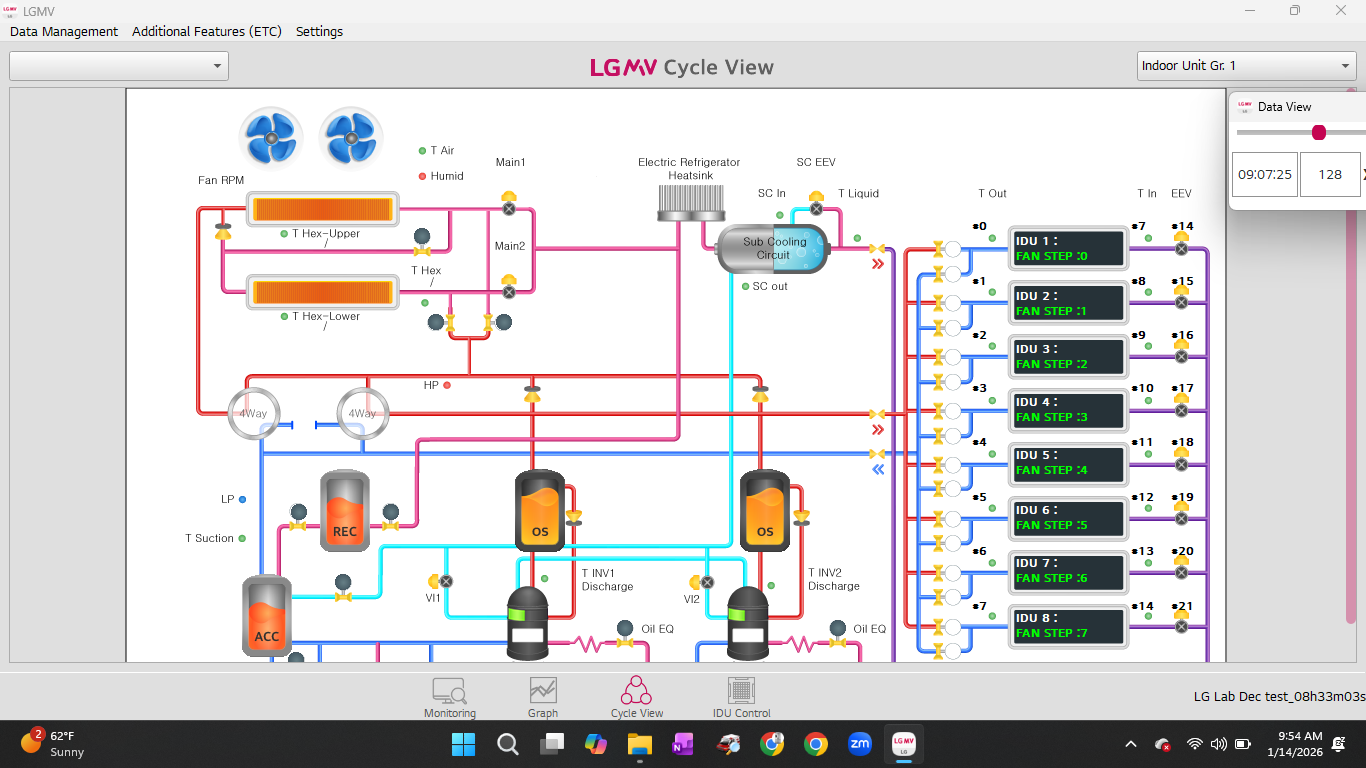

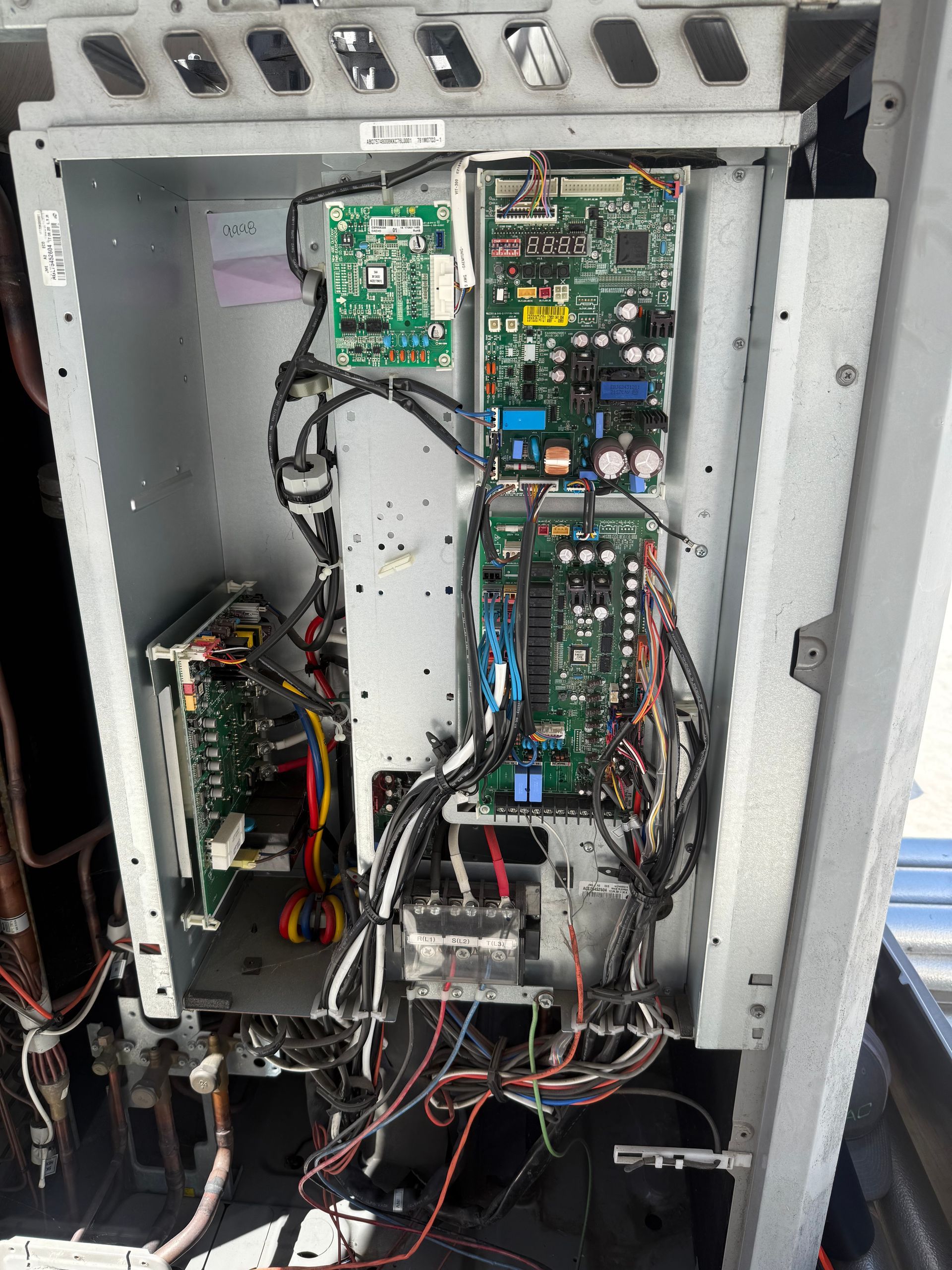

Regular high-level maintenance is essential for the VRF systems of equipment. Each outdoor unit may contain temperature sensors, EEV valves, solenoid valves, and four-way valves. It also houses a variety of electronic PC boards, including a main board, power supply, inverter board, fan boards, and noise filters. Notably, the Multi V 4 outdoor unit can accommodate up to 11 PCBs. Meanwhile, indoor units typically feature four or five sensors, an EEV valve, as well as branch box valves and additional sensors. When considering the entire system, the total number of components can reach into the hundreds. Each of these parts requires regular inspection, testing, and recalibration. Specific maintenance procedures must be meticulously followed to guarantee optimal performance and enhance longevity.

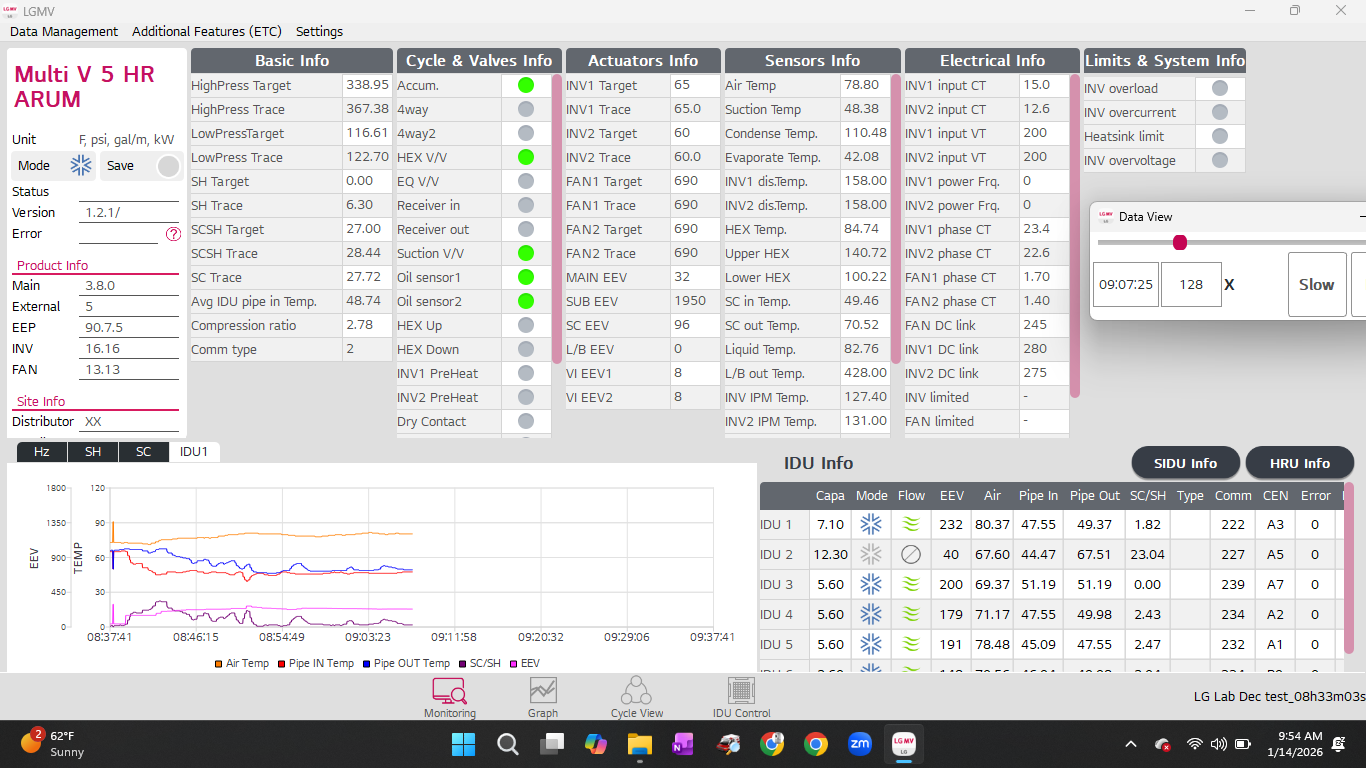

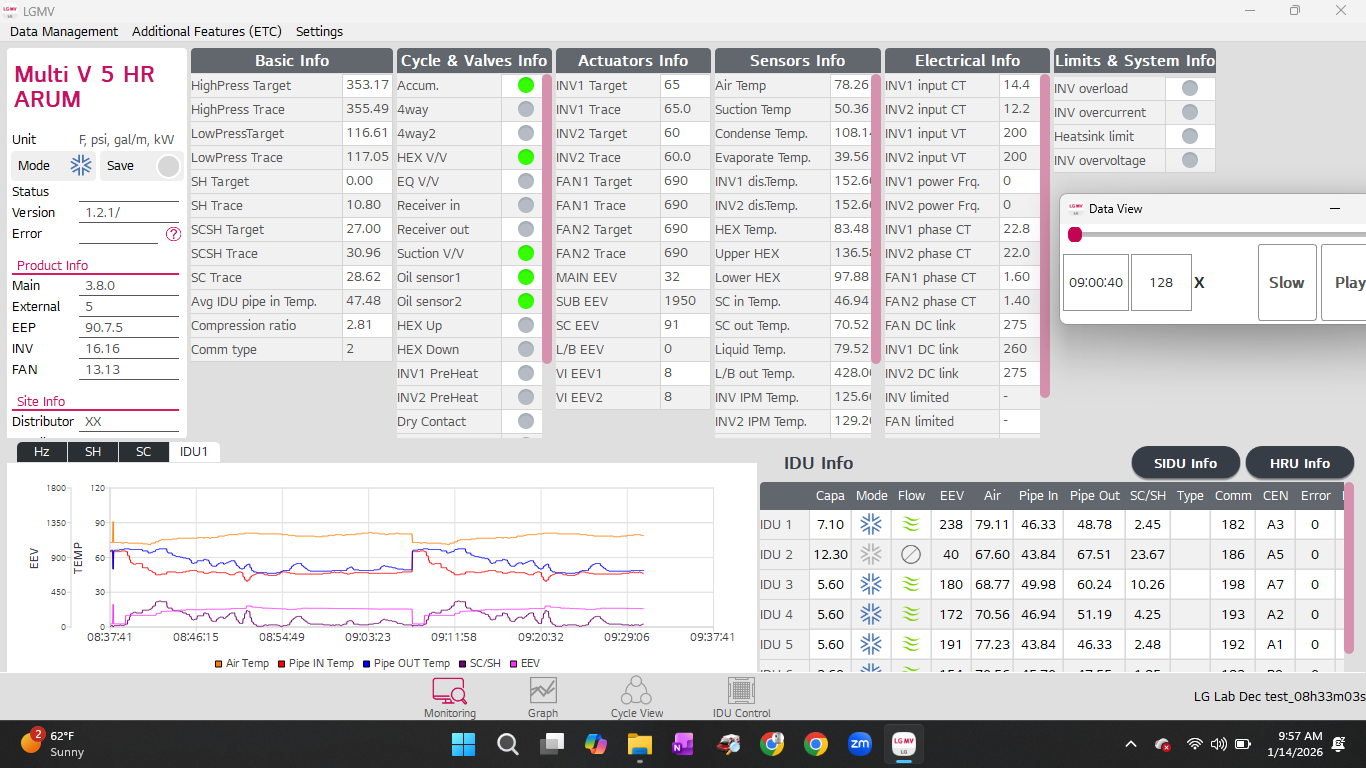

LGMV Service Tool Experts

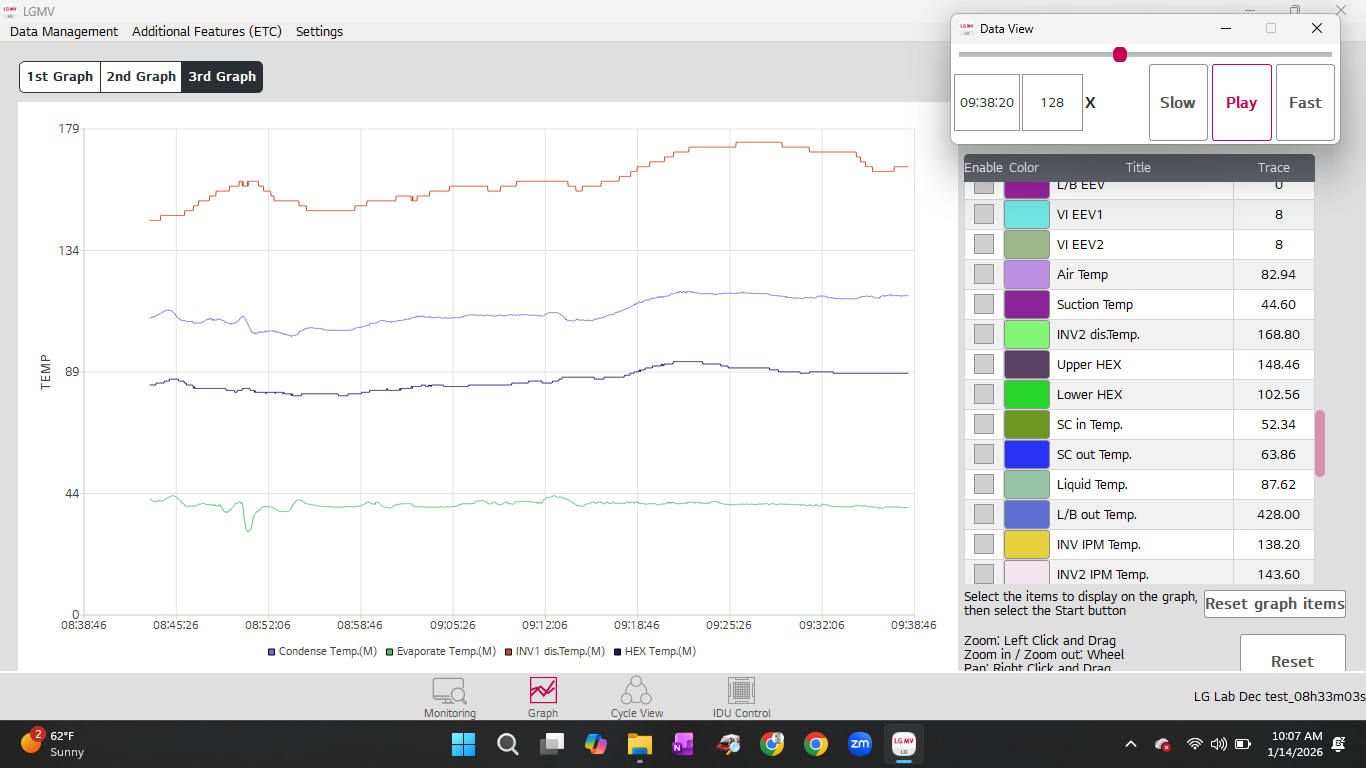

The volume of data generated by a VRF system can be quite daunting. There may be hundreds, if not thousands, of data points to evaluate when assessing system performance. How does a low charge or liquid flood back manifest? These are two of the primary threats to compressor health. Regular monitoring and analysis are essential to identify potential problems before they escalate into significant damage. In addition to the physical upkeep of the equipment, LGMV data analysis is crucial for maintaining a robust system. Reach out to us today; your system might qualify for a FREE check-up.

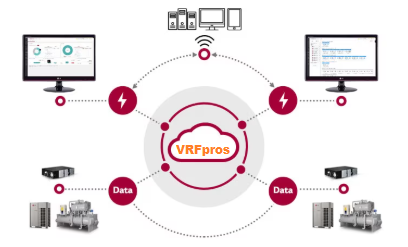

LG System Remote Monitoring

Access equipment data and diagnostic tools remotely to address issues, significantly reducing the need for on-site technician visits and lowering related labor and travel expenses. Real-time monitoring of HVAC equipment's performance and health allows technicians to detect potential problems early, avoiding costly downtime. Technicians receive immediate error notifications for faulty HVAC systems. Maintenance visits can be arranged based on the actual condition of the equipment. This strategy guarantees that your technicians arrive equipped with the necessary tools, parts, and knowledge, improving the efficiency of maintenance visits.